Reasons Why Your Business Needs an Induction Forging Machine

In today’s competitive industrial landscape, investing in advanced technology is not a luxury—it is a necessity. One such revolutionary piece of equipment is the induction forging machine. This cutting-edge technology offers unparalleled advantages, transforming manufacturing processes, reducing costs, and improving productivity. Here, we delve into the critical reasons why your business needs an induction forging machine.

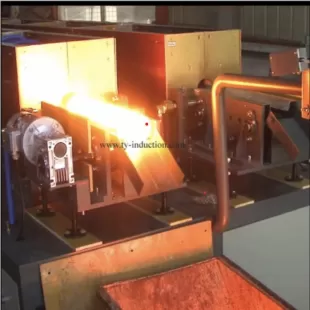

What Is an Induction Forging Machine?

An induction forging machine utilizes electromagnetic induction to heat metals rapidly and precisely. Unlike traditional methods, this process ensures efficient energy use and produces consistent results. It is ideal for applications requiring precision and reliability, such as in the automotive, aerospace, and construction industries.

1. Unmatched Energy Efficiency

Induction forging machines are renowned for their energy-efficient performance. By focusing energy directly on the material to be heated, these machines reduce wastage significantly. Unlike gas-fired furnaces, which lose heat to the surroundings, induction machines deliver targeted heating, lowering energy consumption and cutting operational costs.

Key Benefits:

Reduction in energy bills by up to 30%.

Lower carbon emissions, supporting sustainable practices.

Optimized heating cycles for faster processing.

2. Precise and Consistent Heating

The core advantage of induction forging lies in its ability to provide precise and uniform heating. This ensures that every workpiece achieves the desired properties, minimizing defects and maximizing quality.

Why Precision Matters:

Enhances product strength and durability.

Reduces the risk of material deformities.

Supports tight tolerances required in advanced manufacturing.

3. Increased Productivity

With induction forging, the time required to heat materials is dramatically reduced. This leads to higher throughput and enables businesses to meet tight deadlines without compromising on quality.

Productivity Gains:

Faster heating reduces cycle times.

Automation capabilities streamline workflows.

Improved uptime due to reduced maintenance needs.

4. Superior Safety Standards

Traditional heating methods often expose workers to high temperatures and open flames, posing significant safety risks. Induction forging eliminates these hazards by offering a contactless heating process.

Enhanced Safety Features:

No exposure to harmful emissions.

Reduced risk of workplace injuries.

Environmentally friendly operation with minimal noise.

5. Adaptability Across Industries

The versatility of induction forging machines makes them indispensable across various industries. From shaping gears in the automotive sector to forging aerospace components, their applications are virtually limitless.

Further reading:Key Factors in Selecting Animal Feed Flour Mills

Industries Benefiting from Induction Forging:

Advantages of Low-Fouling Finned Tube Exchangers in Heat Transfer EfficiencyAutomotive: High-strength parts with precision engineering.

Aerospace: Lightweight yet robust components.

Construction: Reliable tools and hardware production.

6. Cost-Effectiveness in the Long Run

Although the initial investment in an induction forging machine may seem substantial, the long-term savings it delivers are undeniable. Lower energy bills, reduced material wastage, and minimal maintenance costs ensure a fast return on investment.

Economic Advantages:

Reduced reliance on consumables like fuel.

Lower labor costs due to automation.

Enhanced machine lifespan through robust design.

7. Environmentally Friendly Technology

Sustainability is more than a buzzword—it’s a business imperative. Induction forging aligns perfectly with green initiatives by reducing energy consumption and emissions.

Sustainability Highlights:

Complies with strict environmental regulations.

Reduces the carbon footprint of manufacturing operations.

Promotes responsible use of resources.

8. Scalability for Business Growth

Whether your production demands are small-scale or industrial-grade, induction forging machines can scale operations to meet your needs. Their modular design allows for easy upgrades as your business grows.

Scalability Advantages:

Flexible configurations for diverse requirements.

Easy integration with existing production lines.

Adaptability for future technological advancements.

9. Competitive Edge in the Market

Investing in an induction forging equipment demonstrates a commitment to innovation, quality, and efficiency. This sets your business apart in a crowded marketplace, giving you a distinct competitive advantage.

Market Impact:

Attracts clients seeking reliable suppliers.

Enhances brand reputation for technological leadership.

Opens doors to high-value contracts in demanding industries.

Conclusion

An induction forging machine is more than just an industrial tool; it’s a strategic investment in the future of your business. Its unmatched energy efficiency, precision, and versatility make it indispensable for modern manufacturing. By adopting this technology, you can enhance productivity, reduce costs, and build a sustainable and competitive business model.

93

0

0

All Comments (0)

Previous: Key Factors in Selecting Animal Feed Flour Mills

Next: Industrial Cold Water Machine: Top 5 Benefits for Your Business

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments