Journal Bearing vs Thrust Bearing: Key Differences Explained

Apr. 21, 2025

Journal Bearing vs Thrust Bearing: Key Differences Explained

When selecting the right bearing for a specific application, it’s essential to understand the differences between various bearing types. Two commonly discussed options are the journal bearing and the thrust bearing. While both serve as essential components in machinery to reduce friction and support rotating parts, they are designed for distinct purposes. Understanding these differences will help you make an informed decision on which type of bearing is best suited for your specific needs.

What is a Journal Bearing?

A journal bearing is a type of bearing that supports a rotating shaft. It consists of a sleeve or bushing that allows the shaft to rotate within it with minimal friction. This type of bearing relies on a thin film of lubricant to reduce wear and tear. Journal bearings are commonly used in high-speed applications such as motors, engines, and turbines.

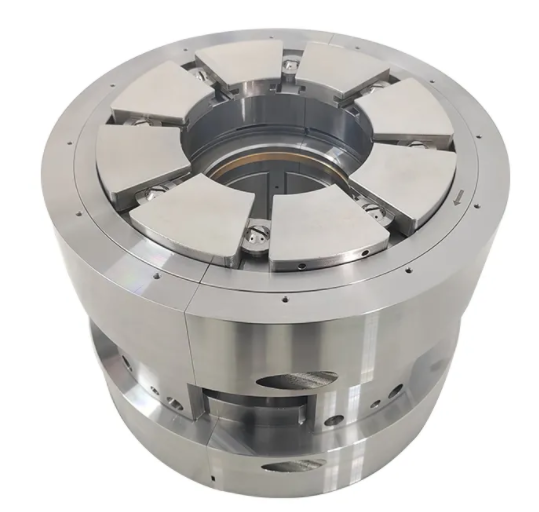

What is a Thrust Bearing?

A thrust bearing, on the other hand, is designed to handle axial loads (forces along the axis of the shaft). It is used to support loads in the direction of rotation, preventing the shaft from moving axially. Thrust bearings are typically used in applications such as gearboxes, automotive clutches, and pumps.

Key Differences Between Journal Bearings and Thrust Bearings

| Feature | Journal Bearing | Thrust Bearing |

|---|---|---|

| Primary Function | Supports radial loads (rotation around shaft) | Supports axial loads (along the shaft axis) |

| Load Handling | Handles radial or side loads | Handles axial loads only |

| Design | Sleeve or bushing supporting the shaft | Specialized components that absorb axial force |

| Applications | Motors, turbines, compressors | Gearboxes, automotive clutches, pumps |

| Lubrication | Requires continuous lubrication for smooth operation | Lubrication necessary but differs in method and location |

| Advantages | Simple design, cost-effective, good for high-speed rotation | Ideal for handling heavy axial loads, efficient in constrained spaces |

| Disadvantages | Limited load capacity, more wear in high-load conditions | Not suitable for radial loads, complex design in some cases |

| Price | Generally more affordable | Can be more expensive due to complex design |

Which One is Suitable for Your Situation?

If you are looking for a bearing to support a rotating shaft with minimal friction in high-speed applications, such as motors or turbines, a journal bearing may be the right choice for you. This type of bearing is often favored in systems where radial load is the primary concern, and its relatively simple design can make it a cost-effective option.

If you need a bearing that can handle axial loads in applications like automotive clutches, pumps, or gearboxes, a thrust bearing would be your best bet. Thrust bearings are specifically designed for these high-load, axial force applications and can ensure smooth operation in these demanding environments.

Purchase and Usage Suggestions

For Journal Bearings:

Use journal bearings if your application involves high-speed rotating machinery where radial loads are predominant.

Consider buying a journal bearing with advanced lubrication features to minimize wear over time.

Maintenance tip: Regular lubrication and inspection are essential to keep journal bearings operating at peak efficiency.

For Thrust Bearings:

Use thrust bearings in applications where axial load support is critical, such as in automotive or industrial machinery.

If your equipment experiences significant axial loads, choose a thrust bearing that is designed specifically for heavy-duty applications to ensure longevity and reliability.

Maintenance tip: Proper alignment and lubrication are key to the performance of thrust bearings.

Decision-Making Guide: Which Bearing is Best for You?

Consider the load type: Are you dealing with radial (rotating) or axial (along the shaft) loads?

Think about space constraints: Some applications, like automotive gearboxes, may require the compact nature of a thrust bearing.

Evaluate cost and maintenance: Journal bearings tend to be more affordable and easier to maintain, but thrust bearings might be necessary for specific applications that handle high axial forces.

By understanding the key differences between journal bearings and thrust bearings, you can select the right type for your needs and ensure the smooth operation of your machinery. If you're still unsure, consulting with a bearing supplier or engineer may help you make the most informed decision.

21

0

0

All Comments (0)

Previous: None

Next: What Are the Performance Benefits of Fixed Lobe Bearings in Turbines

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments